Category

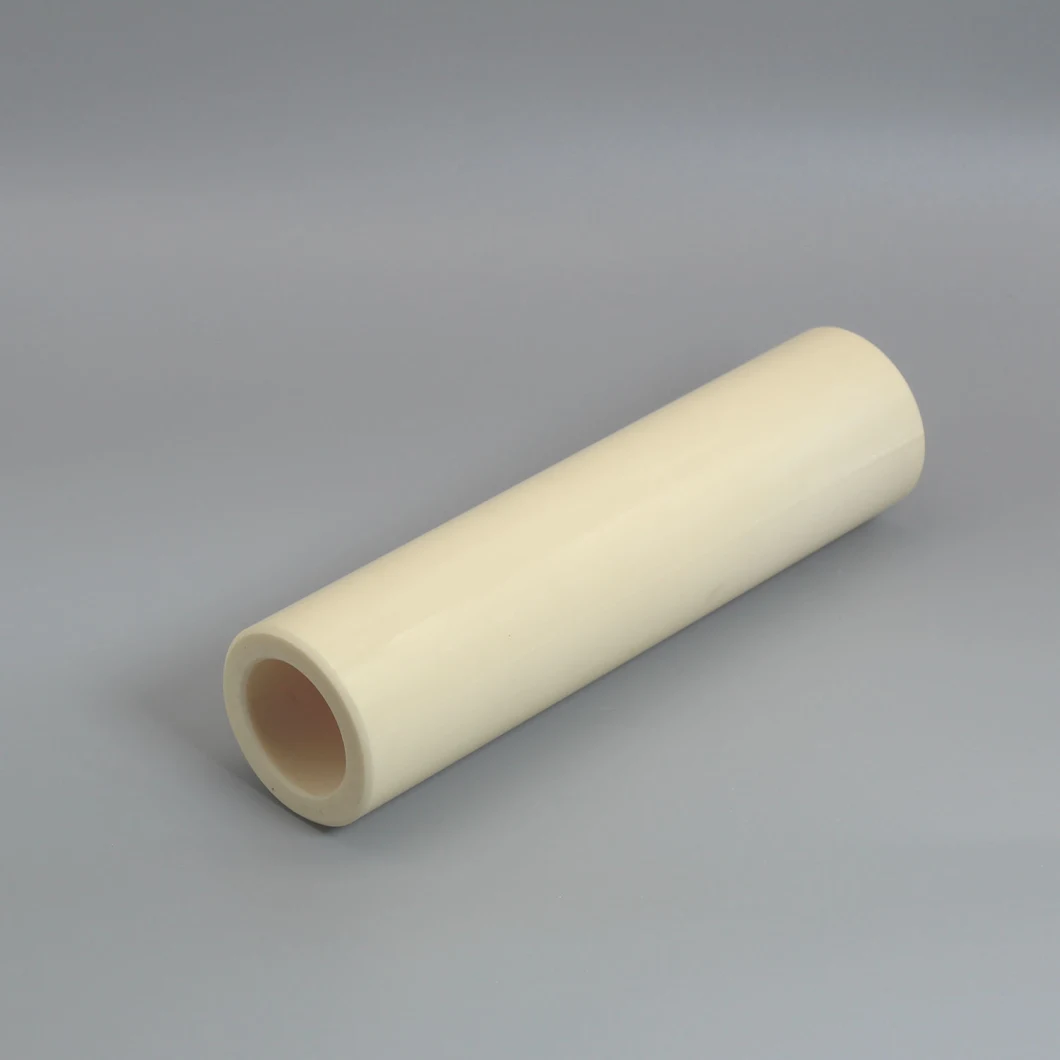

Alumina Ceramic Tube Ceramic Shaft with Customization Available

Technical Parameters Material Introduction Our alumina ceramics are made from synthetic raw materials with aluminum conc

Basic Info

| Shipping | Express/ Air/ Sea |

| Packaging | Individual Packing |

| Sample | Available |

| Transport Package | Cartons and Pallets |

| Origin | Wuxi, China |

| Production Capacity | 1000000/Month |

Product Description

Technical Parameters

| Description | Technical Parameters (Units) | 99% Al2O3 | 95% Al2O3 | MgO/ SiO2 | 3Al2O3/ 3SiO2 | 2MgO/ 2Al2O3/ 5SiO2 | ZrO2 |

| (Al2O3>=99%) | (Al2O3>=95%) | / | / | / | (ZrO2>=94%) | ||

| Physical Specification | Density (g/cm3) | 3.85 | 3.6 | 2.8 | 3 | 2.5 | 5.9 |

| Water Absorption (%) | 0 | 0 | 0 | 3 | 3 | 0 | |

| Sintering Temperature (ºC) | 1690 | 1670 | 1350 | 1300 | 1350 | 1650 | |

| Mechanical Specification | Hardness (HV) | 1700 | 1600 | 800 | 1000 | 800 | 1400 |

| Fracture Toughness (Mpa·m0.5) | 4 | 3-4 | / | / | / | / | |

| Compression Strength (Kgf/cm2) | 30000 | 25000 | 4000 | 6000 | 3500 | 25000 | |

| Thermal Specification | Operating Temperature (ºC) | 1500 | 1400 | 1100 | 1000 | 1000 | 1600 |

| Coefficient of Thermal Expansion (/ºC) | 8x10-6 | 8x10-6 | 6x10-6 | 6x10-6 | 4x10-6 | 10x10-6 | |

| 0-1000ºC | |||||||

| Heat Conductivity (W/m·K) | 31 | 22 | 2.5 | 4.2 | 1.3 | 3 | |

| Electric Specification | Volume Resistivity (Ω.cm) | >1012 | >1012 | >1012 | >1012 | >1012 | >1012 |

| Insulation Breakdown Strength (KV/mm) | 18 | 16 | 10 | 10 | 10 | 15 | |

| Dielectric Constant/ 1Mhz(E) | 10 | 9.5 | 5.8 | 6 | 6 | 12.5 |

Material Introduction

Our alumina ceramics are made from synthetic raw materials with aluminum concentrations of more than 80% Al2O3 to 99.7%Al2O3. The material composition is selected according to the technical and economical requirements. In this way, high hardnessand strength or good wear resistance in various tribological composition can be achieved. Aluminum oxide is extremely thermallystable and resistant against corrosion at very high temperatures.

Wuxi Pladder Technology

We have more than 10 years' experience OEM/ ODM ceramic products for worldwide customers and various industrialapplications. Our service covers everything from technical design, supply management and after-sales maintenanceof applied project. Perfect quality control system, techniques and advanced equipments enabled us to providewow service to our loyal customers.Core Philosophy: Sincerity and win-win cooperation.Company Vision: Work for reliability and innovation.

Production Equipments

Products & Applications

-Ceramic structural parts

Application: Electronics, Mechanical engineering, chemicals, textiles...-Ceramic blades

Application: Home kitchen tools, beauty care, animal husbandry...-Ceramic powder box

Application: sealing of industrial gas or liquid-Ceramic plates

Application: thermal power, steel, metallurgy, mechanical, colliery, chemicals, port, paper-making industry...-Ceramic sensor support

Application: Automobile industry, industrial automation, air conditioner, compressor, pump, petroleum, chemicals...

Certification

We are open for general question and discussion. Welcome to contact us today!