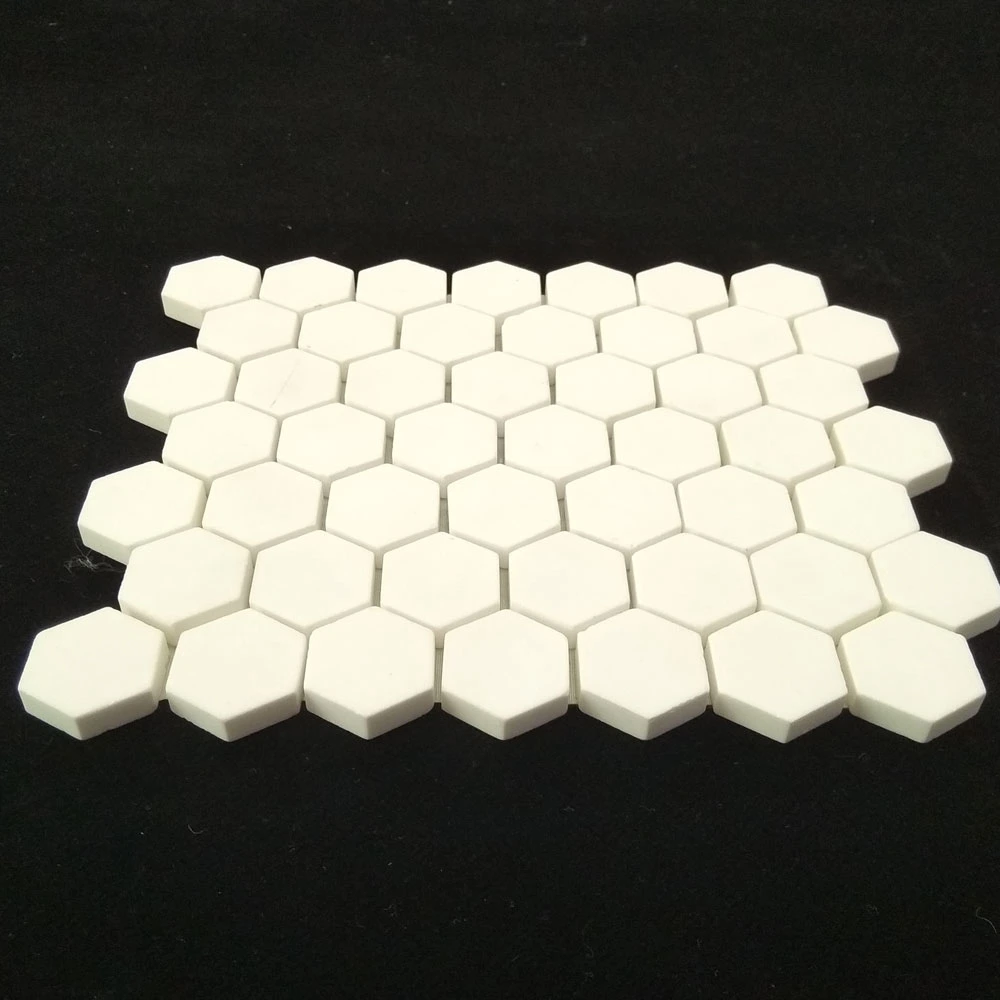

95 Alumina Oxide Ceramic Hexagon Tiles Liners

Basic Info

| Model NO. | Ceramic Hexagon Tiles Liners |

| Wear Rate ‰ | <0.1 |

| Ceramic Mohs Hard Ness | 9 |

| Shipping Way | Fob, CIF, DDP, DDU etc |

| Size | Customzied |

| Shape | Square |

| Export Markets | Global |

| Certification | ISO |

| Function | Grinding |

| Sample Time | 3-15 Days |

| Bulk Order Time | 15-30 Days |

| Customized | Accept |

| Shipping Mark | Accept |

| Transport Package | Carton Package, Then on Pallet |

| Specification | Al2O3 over 92% |

| Trademark | ZIBO QIMINGXING NEW MATERIAL |

| Origin | China Shandong Zibo |

| HS Code | 6909120000 |

| Production Capacity | 17000 Tons Per Year |

Product Description

95 Alumina Oxide Ceramic Hexagon Tiles LinersPicture:

Other Hot Sale :

Product Introduction :

QMX ceramic lining pieces include Hexagonal Tiles, Square, or rectangular linings pieces with/without dimples.

The bulk pieces can be stuck on nylon mesh, kraft paper, and Acetate cloth to get the mats with sizes:150x150mm, 250x250mm, 500x500mm mats, etc.

The small pieces can also be vulcanized into the rubber backed panel or pulley lagging pads.

1.Square tile: 10x10x3~10mm, 17.5x17.5x3~15mm, 20x20x3~15mm, etc.

2.Ceramic Plate: 100x100x6~50mm, 150x100x6~50mm, etc.

3.Hexagonal tile: S12.5xT3~20mm, S23.5xT6-25mm

4.Dimple tiles: 20x20x4-10+1(with 5 dimples), 20x30x5~15+1(with 18 dimples), 20x20x5-10mm( with 13 dimples)

5.Ceramic Block: 40x40x40mm, 45x45x50mm,32x32x22mm, 38x38x38mm,etc.

6.Ceramic Cylinder/rod: 6x6mm,15x15mm,20x20mm, 31x31mm,40x40mm, 45x50mm, 50x50mm etc.

| Category | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Density | >3.50g/ cm3 | >3.60g/cm3 | >3.65g/cm3 | >3.70g/cm3 | >3.83g/cm3 | >4.10g/cm3 | >5.90g/cm3 |

| HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Bending Strength MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Compression strength MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Fracture Toughness KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Wear Volume | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

NOTE: Support customization, please send the parameters of your specific requirements to our online staff.

Our Company :

1. Established in 1997,20 years experience in wear solutions products.2. The factory is under expanding, the total construction area is 50,000 sqm.3.ISO9001:2000 certified,over 260 staffs.4. Three Own-designed production lines, the ball mils are own produced.

The company specializes in the production of HC series wear-resistant ceramic liners(alumina ball, zirconium silicate ball, zirconia toughed alumina ball, zirconium ball), agate ball, polyurethane ball, 92/T95/ZTA wear-resistant ceramic liner (alumina liner, zirconium toughed aluminum composite liner, zirconia plate), three-in-one, Two-in-one vulcanized ceramic runner sheet, ceramic mending compound, ceramic lining cyclone, ceramic lining pipe.

Packaging :

1. Packaged with carton box.2. There are compartments in the cartons to prevent friction.

About package and shipping marks all could be customized.Kindly contact with Amy please : )

FAQ :

Q: Are you a trading company or manufacturer?

A: We are a?factory

Q: Is the sample free?

A: Yes, we offer free samples. The sample air shipping fee will be returned when the bulk order

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity

Q: What are your terms of payment?

A: 30% T/T in advance, balance before shipment

Q: Accept customized?

A: Yes. Kindly send all your details to our work.

If you have any questions, kindly contact Amy : )