Category

Zirconia Toughened Alumina (ZTA) Composite Ceramic Lining Liner From Qimingxing

Overview Product Description 1. Detailed description Zirconia Toughened Alumina(ZTA) composite ceramic lining board intr

Basic Info

| Hexagonal Tile | S12.5xt3~20mm, S23.5xt6-25mm |

| Dimple Tiles | 20X20X4-10+1(with 5 Dimples), 20X30X5~15+1(with 18 |

| Ceramic Block | 40X40X40mm, 45X45X50mm,32X32X22mm, 38X38X38mm,etc. |

| Ceramic Cylinder/Rod | 6X6mm,15X15mm,20X20mm, 31X31mm,40X40mm, 45X50mm, 5 |

| Al2O3 | 75% |

| Zro2+Y2o3 | 21% |

| Density | 4.15 g/cm3 |

| Hv 20 | 1350 |

| Rock Hardness Hra | 90 |

| Bending Strength MPa | 400 |

| Compression Strength MPa | 2000 |

| Fracture Toughness Kic Mpam 1/2 | 5.0 |

| Wear Volume | 0.05 Cm3 |

| Transport Package | Box |

| Specification | customized size |

| Trademark | firstar |

| Origin | China |

| HS Code | 6909120000 |

| Production Capacity | 400t/Month |

Product Description

Product Description1. Detailed description

Zirconia Toughened Alumina(ZTA) composite ceramic lining board introduces ZrO2 and Y2O3 with similar lattices to Al2O3 in the ceramic formula, It can refine grains, promote sintering and improve fracture toughness. The fracture toughness of zirconia ceramics is greater than or equal to 7.5MPa•m1/2, which greatly improves the toughness of ceramics.

ZTA ceramic wear liner uses advanced vulcanization technology to vulcanize ZTA ceramic made of alumina and zirconia in rubber, and can also vulcanize ceramic rubber directly on steel plate. The firmness ensures the reliability of wear resistance and impact resistance.

ZTA Ceramic wear Liner (NMC-ZTA) is used as an anti-wear lining on equipment with large conveying volume, large material and high impact under normal temperature environment.

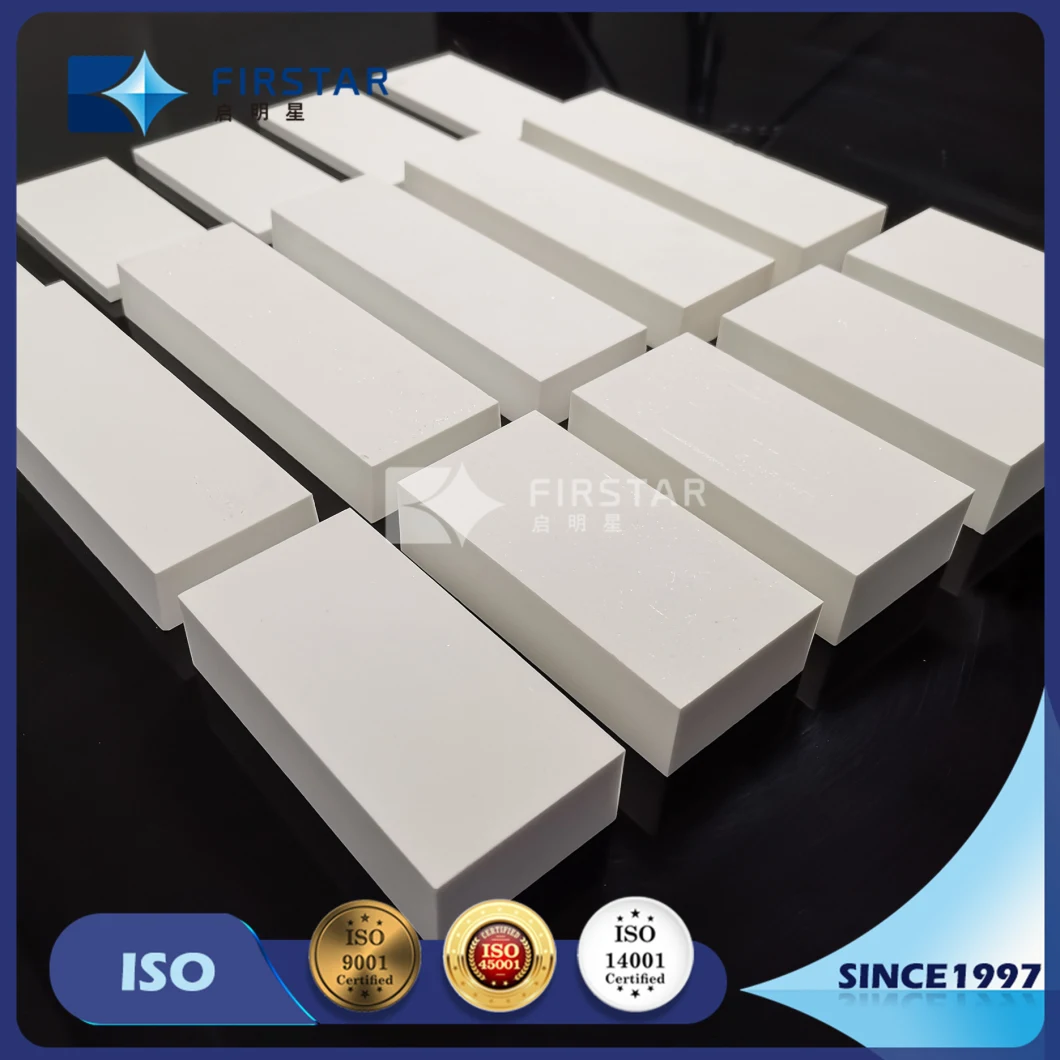

> High hardness > Superior abrasion and impact resistance > Corrosion and chemical resistance > Light weight > Easy installation by epoxy resin or bolt > Improve your working environment-noise, vibration and safety3. Product Specification:- Square tile: 10x10x3~10mm, 17.5x17.5x3~15mm, 20x20x3~15mm, etc.- Ceramic Plate: 100x100x6~50mm, 150x100x6~50mm, etc.- Hexagonal tile: S12.5xT3~20mm, S23.5xT6-25mm- Dimple tiles: 20x20x4-10+1(with 5 dimples), 20x30x5~15+1(with 18 dimples), 20x20x5-10mm( with 13 dimples)- Ceramic Block: 40x40x40mm, 45x45x50mm,32x32x22mm, 38x38x38mm,etc.- Ceramic Cylinder/rod: 6x6mm,15x15mm,20x20mm, 31x31mm,40x40mm, 45x50mm, 50x50mm etc.5. Ceramic wear lining tiles for a variety of applications:Processing equipment:l Pharmaceutical clean roomsl Food processing plantsl Grain handlingl Mineral processingl Cement manufacturingl Chemical processingl Large Cyclones:l Coal-fired power plantsl Steel Millsl Asphalt Plantsl Petrochemical plantsl Pulp and paper millsDetailed Photos

| Category | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Density | >3.50g/ cm3 | >3.60g/cm3 | >3.65g/cm3 | >3.70g/cm3 | >3.83g/cm3 | >4.10g/cm3 | >5.90g/cm3 |

| HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Bending Strength MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Compression strength MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Fracture Toughness KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Wear Volume | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

Qimingxing offer quality wear and Ant- impact ceramics, in combination with our experienced and competent staff, ensure the increased efficiency and service life of all equipments and materials to which they are applied. - Established Ultrafine Energy Efficiency Technology Research Institute - Increase lifespan of wearable parts - New improved technology and products - Minimal downtime to minimize delays in production - Variety of wear combating options available as a one stop solution - Strong focus on product innovation supported by Chinese Academy of Sciences. - Customized application techniques to suite any wear problem

Certifications

FAQQ: What is your experience in your products?

A: We have 22 years experience in this industry line. We are professional manufacturer in this area.

Q: What is your MOQ?

A: The MOQ is different as per different products, for example, 1 Ton for ceramic ball.

Q: Can you accept small quantity sample order before production?

A: Yes, we can offer sample for your testing first

Q: Can you provide free sample?

A: Yes, within 1kg.

Q: What is your production time?

A: We have large stock for standard products. Normally within 7-10days after receipt the deposit.

Q: What are your payment terms?

A: T/T, L/C, Western Union