High Quality Abrasion Ceramic Lined Wear Resistance Flexible Rubber Hose

Basic Info

| Model NO. | 003 |

| HS Code | 3901200090 |

| Production Capacity | 100000 Units Per Year |

Product Description

The rubber lined steel pipes are designed to be used in various abrasive pumping applications. Applications such as mill discharge, high pressure pumps, long tailings lines, demanding slurry pump applications and gravity pipes. Each end with vulcanized rubber seal fixed flange.Wear-resistant and corrosion-resistant steel lining rubber composite pipe is made of common steel pipe as framework material and using with excellent properties of wear-resistant, corrosion-resistant and heat-resistant rubber as lining layer. It is compounded by special technology with high-performance adhesive. Mainly used in metallurgy, electric power, chemical industry, petroleum, coal, cement and other industries area.

- 1. Excellent Construction

- 2. Good wear resistance and long service life

- 3. High strength and high impact resistance

- 4. Good corrosion resistance

- 5. Wide temperature range

- 6. Quick connection and easy installation

In the mining work, it is widely used in the mine tailings conveying system, coal mine backfilling and related pipe system fields. In particular, the pipeline is very suitable for conveying the temperature between -50°C to +150°C medium, which is easy to wear and corrosion. We can increase the wall thickness at the pipe corner according to the customer's demand, thus extending the service life. Meanwhile, the service life of the rubber-lined steel pipe can reach 15-40 years in general. The pipe can be rotated nearly 90 degrees after 6-8 years of service. Each time of rotation can extend the serving life, Steel pipe can be repeatedly lined with rubber for three to four times, thus it reducing the use of costs in further.

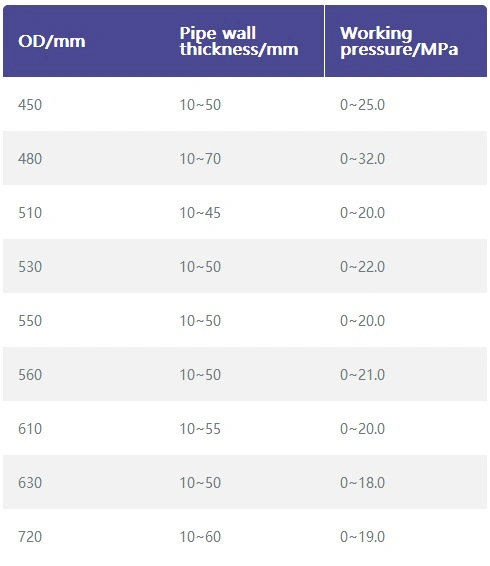

Product ParametersParts of specification for rubber-lined pipe

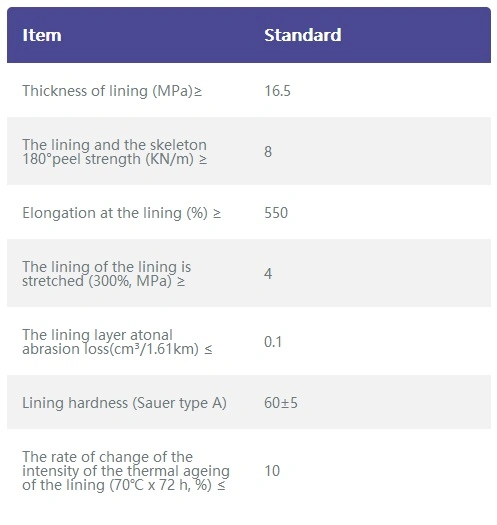

Physical Properties of rubber-lined pipe