Category

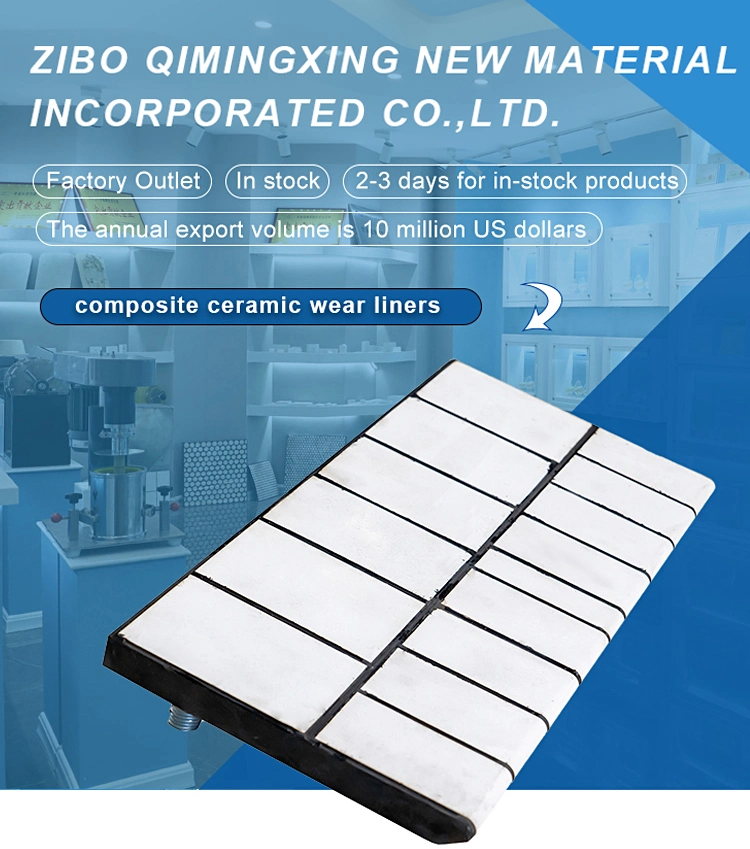

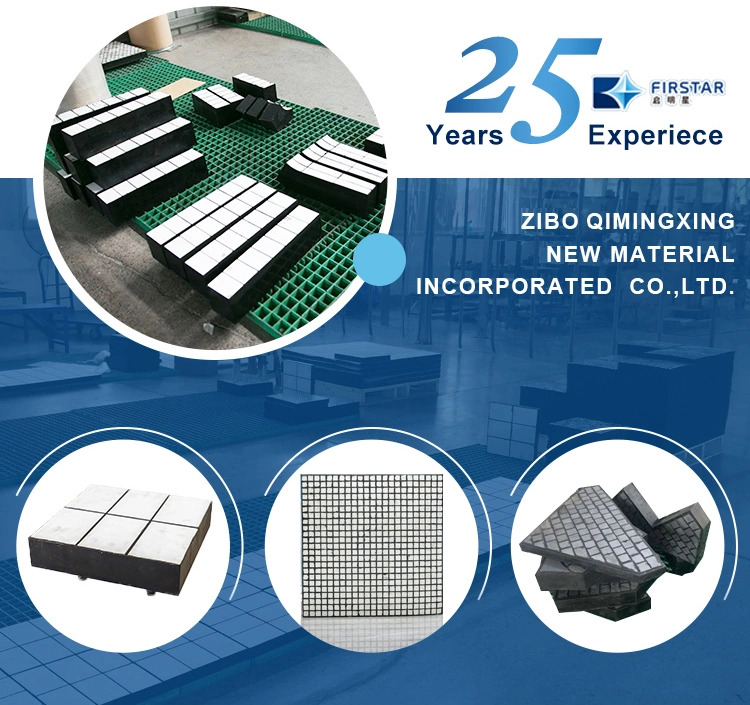

GB Anti-Wear and Anti-Impact Ceramic Rubber Panel Wear Lining Plate Ceramic Composite Wear Liner

Overview GB Anti-Wear And Anti-impact Ceramic Rubber Panel Wear Lining Plate Ceramic Composite Wear Liner Product Descri

Basic Info

| Model NO. | Rubber Ceramic Wear Liners |

| Ceramic Tile | 92%, 95%, Zta |

| Ceramic Thickness | 3-75mm |

| Ceramic Mohs Hard Ness | 9 |

| Wear Rate ‰ | <0.1 |

| Steel Plate | Q235A |

| Steel Thickness | 3-10mm |

| Whole Plate Size | Customzied |

| Usage | Lining of Equipment and Chute |

| Factory | Yes |

| OEM | Yes |

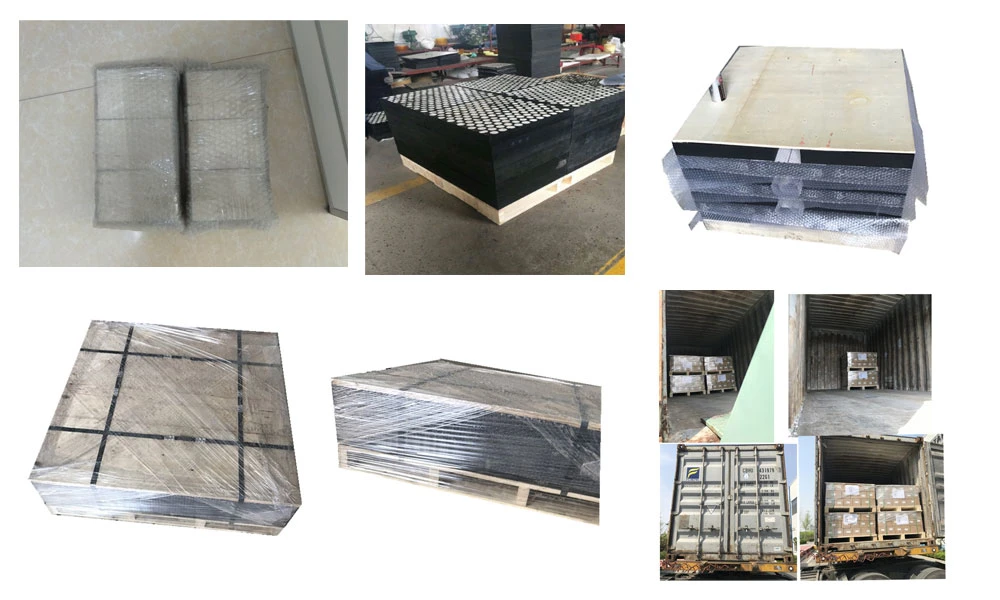

| Transport Package | Plywood Case/Pallet |

| Specification | Customized |

| Trademark | ZIBO QIMINGXING NEW MATERIAL |

| Origin | China, Shandong, Zibo |

| HS Code | 6909120000 |

| Production Capacity | 18000 Tons/Years |

Product Description

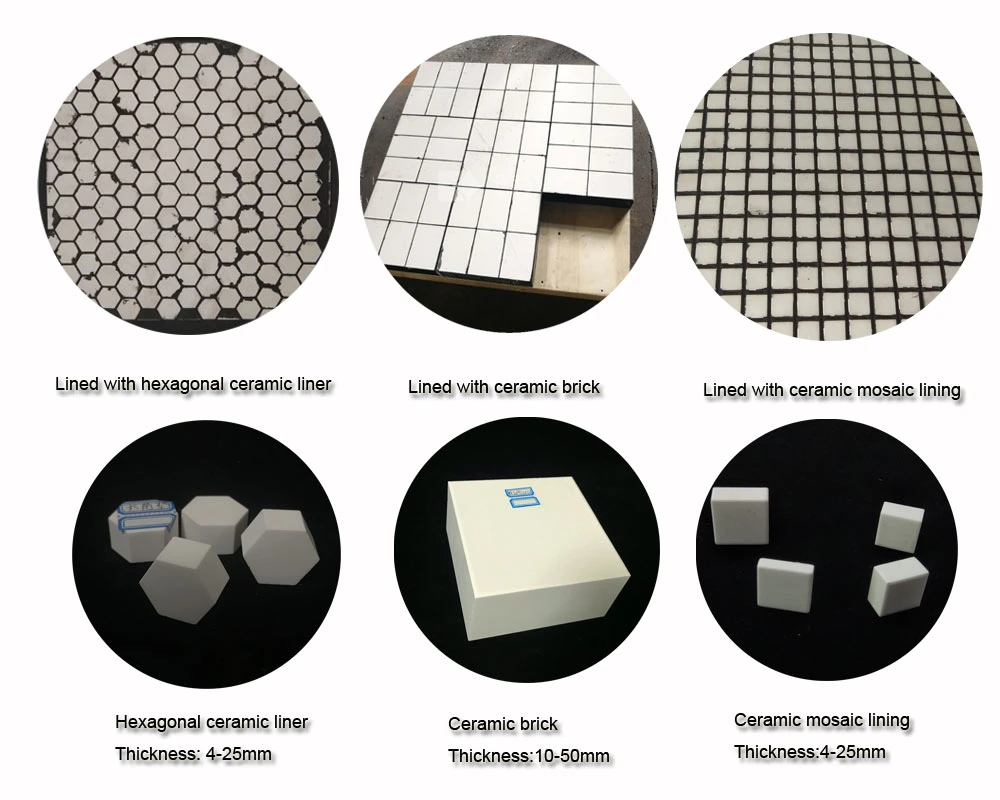

GB Anti-Wear And Anti-impact Ceramic Rubber Panel Wear Lining Plate Ceramic Composite Wear Liner Product DescriptionAlso named wear cermaic parts, wear rubber ceramic plate, wear resistant ceramic pads.

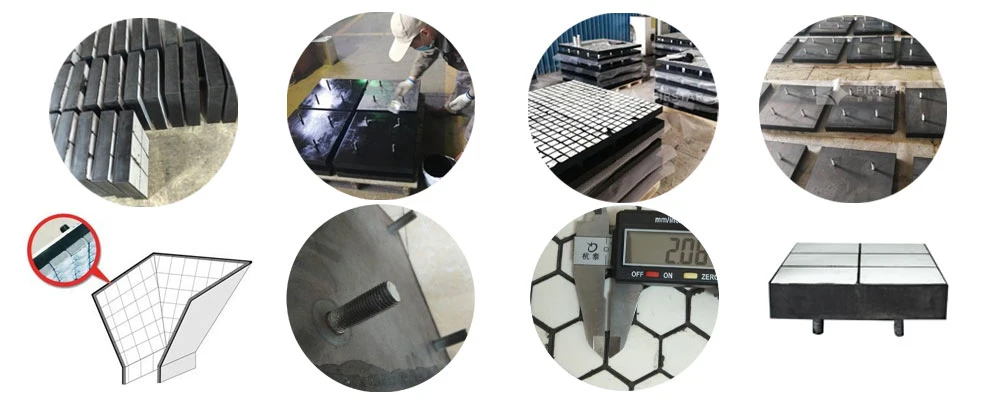

Ceramic rubber composite pads&plate is use of rubber vulcanization process, to embed the wear-resistant ceramic vulcanized into rubber, stick it on the inner all of equipment with the adhesice paste.As customers' requirment, it also can be vulcanized together with steel plate, with bolts or not.Features:It combines wear-resistance of ceramic of ceramic and impact-resistance of rubber, apply to conveying systems equipment work under normal temperture,and can bear some impact.Applications:Ppes and tanksDeflectorsLaundersSpill Face Sloping Walls&Loading ChutesBins&HoppersMill feed components

Product Parameters

| S.No. | Material | Attributes | Properties |

| 1 | Ceramic Tiles | Material | 92%, 95%, T95%,96%, ZTA |

| 2 | Rubber | Component | natural rubber, nitrile-butadiene rubber ,Flame Retardant ,others |

| Density | ~1.4g/cm3 | ||

| Tensile strength at break | ≥15Mpa | ||

| Elongation at break | ≥250% | ||

| Shore Hardness | 45-65 | ||

| Adhesive between tile and rubber | 1.2-3.0 Mpa | ||

| Adhesive between rubber and equipment | ≥3.5 Mpa | ||

| Thermal conductivity.(normal temperature) | 2w/m·k | ||

| Aging period | ≥15 Years | ||

| Working temperature | -50ºC - 200ºC | ||

| 3 | Steel plate | Material | Q235A |

| Density | 7.85g/cm3 | ||

| Thickness | 5-6mm | ||

| 4 | Adhesive | Appearance | Brown glutinous liquid |

| Solid content | 20±3% | ||

| Viscosity | ≥2.5 Mpa | ||

| Peel strength | 48h N/2.5cm≥120 | ||

| Compressive strength | ≥850 Mpa | ||

| Working temperature | -20ºC - 100ºC |

| Whole Plate (mm) | 150x300, 300x300, 450x000, 500x500, 600x450 etc. |

| Ceramic Size (mm) | Square Tile: 10x10, 20x20, 33x33, 50x50, 100x100, 150x100,etc. |

| Hexagonal Tile: 12x3, 12x6, 19x7, 19x12.5, 19x25,etc. | |

| Locking block with lock and groove: 38x38, 40x40, 30x30,etc. | |

| Dimple Tile: 20x20 with 5 dimples, 20x30 with 18 dimples, 20x30 with 13 dimples, 20x20 with 1 semi-spherical surface | |

| Ceramic Thickness (mm) | 3-75mm |

| Alloy Steel Size (mm) | Thickness: 3-10mm |

| Rubber Thickness (mm) | Depends on the impact stress expected. |

FAQ

Q: Are you trading company or manufacturer ?

A: We are factoryQ: Is the sample free ?

A: Yes,we offer free samples. The sample air shipping fee will be return when bulk order.

Q: How long is your delivery time ?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment. Hot Sale Products1. 92%,95%,T95%,99% Alumina ceramic tiles2. ZTA(Zirconia Toughened Alumina) tiles/brick/block 3. Ceramic Rubber and ceramic-Rubber-steel impact resistant liner4. Monolihic Cyclone/ cyclone tiles/Ceramic Lined pipe fittings5. High impact ceramic wearing compound