Category

Wear and Impact Resistant Discharge Chute Zta Rubber Ceramic Wear Liner

Wear and Impact Resistant Discharge Chute ZTA Rubber Ceramic Wear Liner Why Choose US:1. Manufacturer for composite cera

Basic Info

| Model NO. | DB-TCM-I, DB-TCM-II, DB-TCM-III |

| Applications | Mining and Material Processing |

| Use for | Feed Chute, Transfer Chute, Rock Boxes, etc. |

| Ceramic Tiles | 92% or 95% Alumina or Zta Ceramic Tiles, etc |

| Rubber | Natural Rubber |

| Fixing Method | Bolting, Welding, Bonding, etc. |

| Custom | Available in Custom Sizes. |

| Samples | We Provide Samples to Evaluate The Properties. |

| Polyurethane Ceramic Liners | Available |

| Rubber Wear Liners | Available |

| Polyurethane Lining Sheet | Available |

| Quality | Proven Quality, High Wear Resistance |

| Our Advantage | Manufacturer |

| Lead Time | It Depends on The Sizes and Quantity |

| Transport Package | Crate, Pallet |

| Specification | Various |

| Trademark | JZDT |

| Origin | Jiaozuo, Henan, China |

| HS Code | 69091200 |

| Production Capacity | 10000 PCS/Month |

Product Description

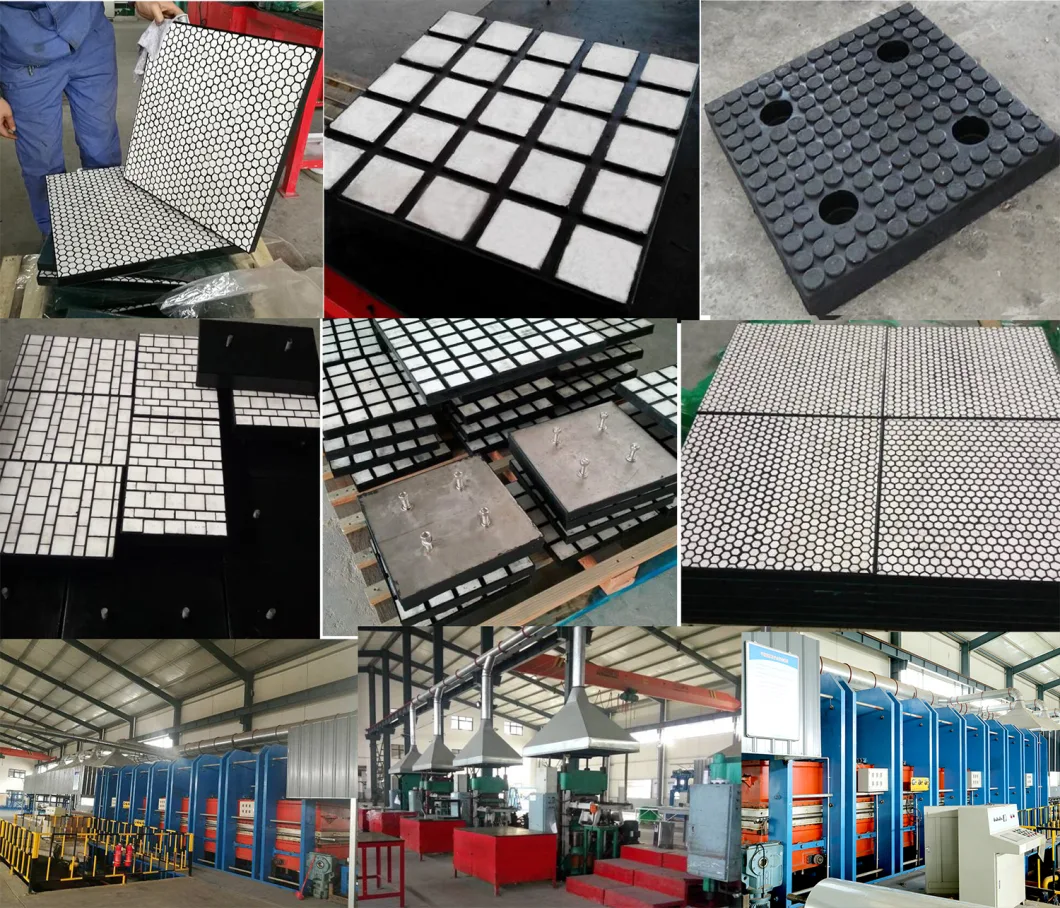

Wear and Impact Resistant Discharge Chute ZTA Rubber Ceramic Wear LinerWhy Choose US:1. Manufacturer for composite ceramic wear liners2. We produce a wide range of wear liners.3. Proven quality.4. ISO9001, ISO14001, ISO45001 certified factory.We manufacture a wide range of composite ceramic liner plates. Ceramic tiles are available in 92%, 95%, 99% or ZTA ceramic.

About composite rubber ceramic wear liner plate.

Rubber ceramic liner plates are high abrasion and impact resistant wear liners for mining, quarrying and mineral processing applications.

High alumina ceramic tiles deliver high wear and abrasion resistance and the rubber cushion helps reduce the impact energy.

Ceramic wear liner plate can extend service life of your facilities considerably, reduce maintenance and shutdown time.

Composite rubber ceramic liner plates are proved optimal wear liners for iron ore mine, copper mine, coal mine, etc.

Ceramic on rubber mats, rubber ceramic mats.

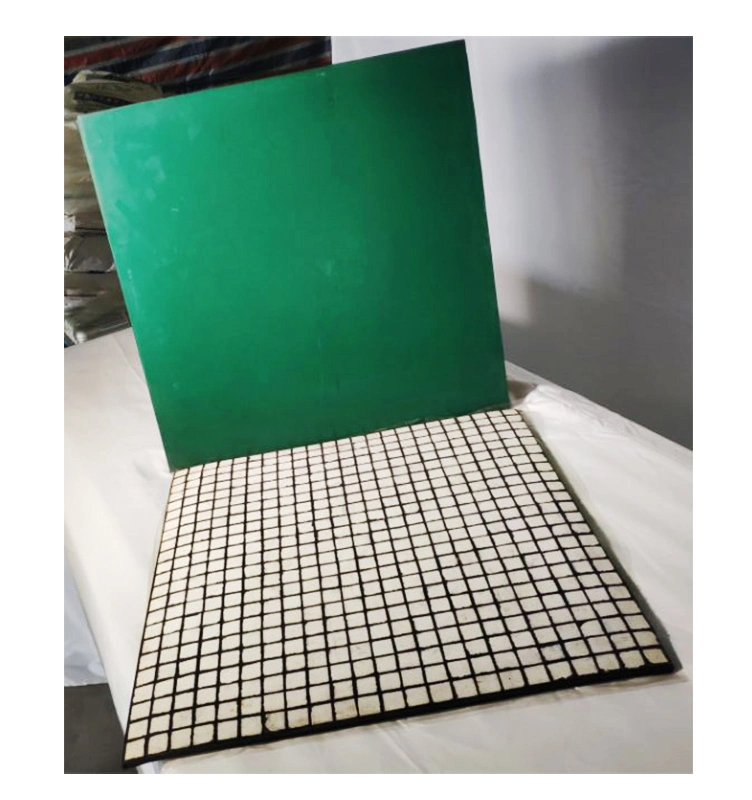

Rubber backed ceramic mats are vulcanizing ceramic tiles into rubber matrix, such ceramic mats do not have steel backing plate. Rubber ceramic mats can be bended to suit the facilities, especially for the curved facility, such as cyclone.

Ceramic on rubber mats can be produced with a cn bonding layer. See below image please, the green layer is cn bonding layer, which can deliver fast and excellent bonding adhesion.

| Ceramic mats | Ceramic Shape | Structure | Overall thickness |

| 500x500x8 | Square, Cylindrical or Hexagonal | 4mm ceramic on 4 mm rubber | 8 |

| 500x500x10 | Square, Cylindrical or Hexagonal | 6mm ceramic on 4 mm rubber | 10 |

| 500x500x14 | Square, Cylindrical or Hexagonal | 10mm ceramic on 4 mm rubber | 14 |

| 500x500x20 | Square, Cylindrical or Hexagonal | 13mm ceramic on 7 mm rubber | 20 |

| 500x500x25 | Cylindrical or Hexagonal | 20mm ceramic on 5mm rubber | 25 |

| 500x500x30 | Cylindrical or Hexagonal | 25mm ceramic on 5mm rubber | 30 |

| Custom-made ceramic mats are also available. | |||

Rubber backed ceramic mats, 4mm ceramic on 4mm rubber.

Ceramic on rubber mats, 14mm hexgon ceramic tiles on 6mm rubber . AF 20mm ceramic tiles on 6mm or 10mm rubber.

Composite rubber ceramic liner plate can also be produced with steel backing plate and studs

Commonly the steel backing plate is 6mm mild steel. SS304 or SS306 stainless steel backing plates are also available.

Ceramic liner plate with steel backing plate and studs.

Composite rubber ceramic wear liner plate with stainless steel plate.

Ceramic wear liner plate can also be produced with polyurethane matrix.

Polyurethane backed ceramic liner plate, ceramic urethane wear liner plate. Polyurethane ceramic wear liners.

Custom ceramic wear liner plates are also available upon request. Custom shape, such as triangle, cerved ones.

About US:

Jiaozuo Debon is a factory producing wear lining products, we can also provide wear solutions for your applications.

More information, just contact Ms Leila Wu