Category

Alumina Ceramic Cyclone Liners Curved Wear Resistant Liner

Details:Product Name:cyclone liner/cyclone liners/Wear Resistant Ceramic Cyclone Liner/cyclone liner vacProduct Material

Basic Info

| Transport Package | by Cartons and Pallet |

| Specification | Customized |

| Trademark | Tiatn |

| Origin | Shandong, China |

| HS Code | 690912 |

| Production Capacity | 17000 Tons Per Year |

Product Description

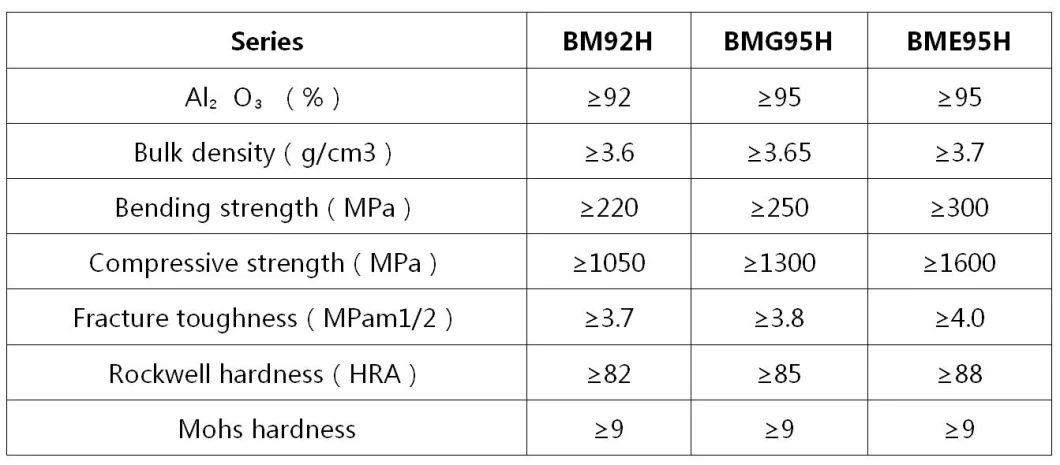

Details:Product Name:cyclone liner/cyclone liners/Wear Resistant Ceramic Cyclone Liner/cyclone liner vacProduct Material:AluminaProduct Color:whiteCertificate:ISO9001Customized: available Product Packaging:25kgs/bag /as requirementsDescription:In order to solve the wear-resistant problem of cyclone separators and improve the service life of cyclone separators, alumina wear-resistant cyclone liner are being popularized. In the case of high temperature corrosion, high temperature wear or high temperature erosion, the arc-shaped alumina wear-resistant ceramic cyclone liner is used. Under the same industrial and mining conditions, its service life is ten to twenty times that of cast stone, wear-resistant alloy cast steel, steel plastic, steel rubber and other materials.Product Advantages:(Perfectly fit design shape) The porcelain type is designed according to the shape of the cyclone , the cone pipe, the water outlet pipe, etc., the structure is reasonable, and there is no gap(High density) ceramics cyclone liners are made of 20-25mm thick, 100 tons of dry pressing, high density and wear resistance(High-quality bonding technology) The wear-resistant ceramic cyclone linersis fixed using modified adhesive and split-layer bonding technology. There is no linear gap, and the bonding is firm and does not fall off. Suitable for harsh working conditions such as high temperature, high impact or dynamic operation(Smooth and flat) The cyclone liners inner wall is smooth, the material is smooth, and the height difference between the ceramics is within 0.5mm, which can maintain a large tangential velocity of the slurry in the cyclone, reduce energy loss, and obtain the best classification and concentration effect.Technical Data

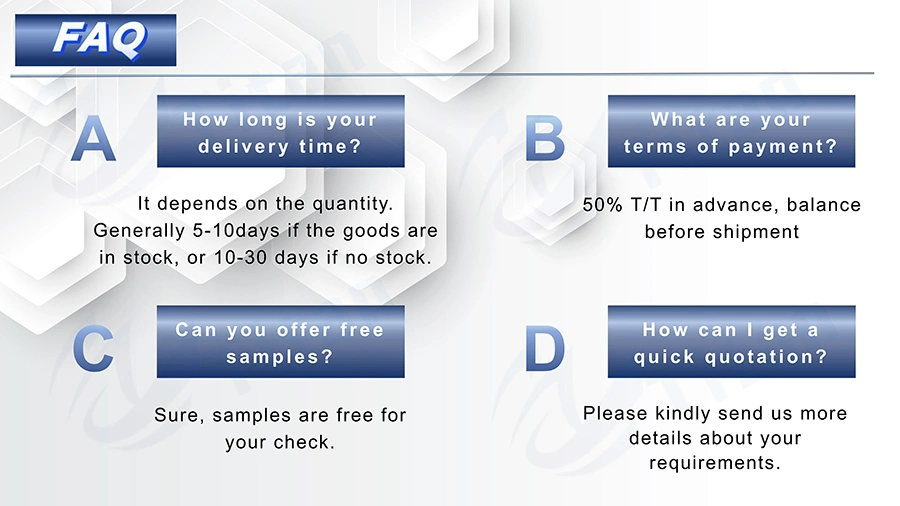

Q&A

Product ImageFactory Photo