Category

Pulley Ceramic Tiles Lagging Rubber Composite Sheet with Cn Bonding Layer

Pulley ceramic tiles lagging rubber composite sheet with CN bonding layerWhy Choose Us: 1. Factory, not a trading compan

Basic Info

| Model NO. | DB-TC |

| Width | 500mm |

| Rubber Lagging | Available. |

| Our Advantage | Manufacturer,Direct Seal |

| Cn Bonding Layer | with a Cn Bonding Layer. |

| Length of Ceramic Lagging | in Pieces or in 10m Rolls |

| Lead Time | 7 Days. |

| Certification | ISO9001, ISO14001, ISO45001 |

| Custom Size | Available |

| Installation | Cond Bonding |

| Transport Package | Crate or Pallet |

| Specification | It depends on quantity and size of ceramic lagging |

| Trademark | JZDT |

| Origin | Jiaozuo, Henan, China |

| HS Code | 4008210000 |

| Production Capacity | 200, 000 Meters/Year |

Product Description

Pulley ceramic tiles lagging rubber composite sheet with CN bonding layerWhy Choose Us:1. Factory, not a trading company.

2. Over 15-year experience.

3. Good delivery time.

4. Proven quality.

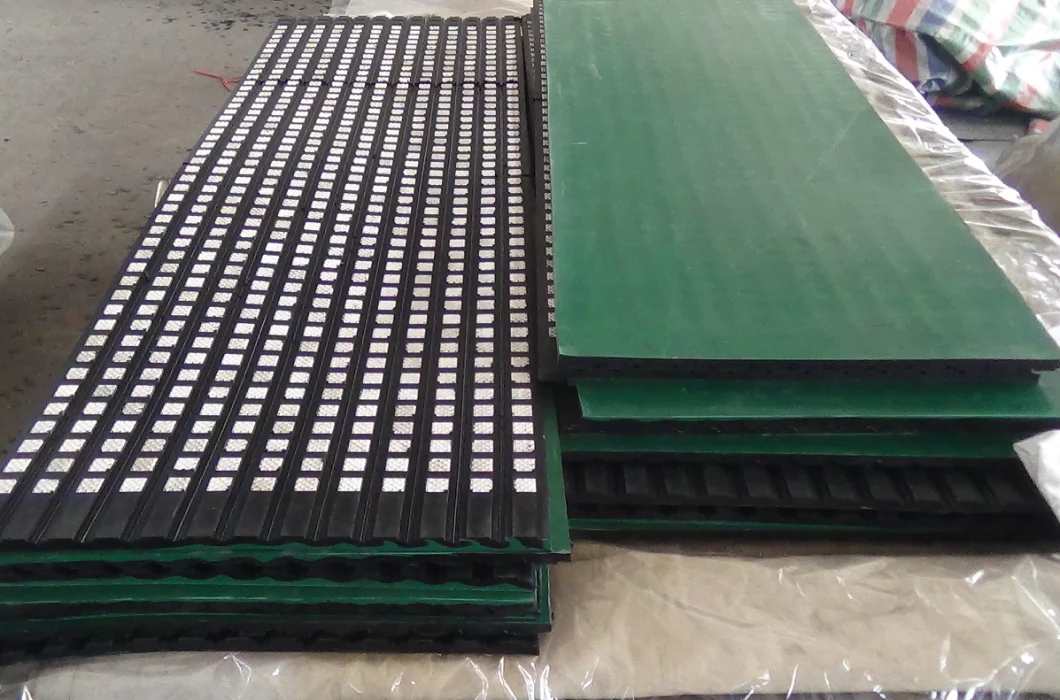

Rubber ceramic lagging sheets for conveyor pulley lagging.

CN layer backed rubber ceramic lagging sheets.

Description of rubber backed ceramic pulley lagging:

Coefficient of friction between conveyor belt and pulley is a very important factor in determining the performance of a conveyor belt on a drive.Low coefficient of friction may cause conveyor belt slippage and lead to more wear of the belt and belt tracking problem. Rubber pulley lagging can reduce slippage and extend service life of conveyor belt.

Ceramic pulley lagging is high wear resistant pulley lagging material, the high alumina tiles increase the wear resistance and friction coefficient. The diamond nibbles considerably improve the belt grip and the wear life of the lagging material.

Ceramic lagging is an optimal solution for conveyor pulleys in tough applications.

Pulley ceramic lagging sheet can be produced with a cn bonding layer. CN layer helps offer fast and higher bonding strength.

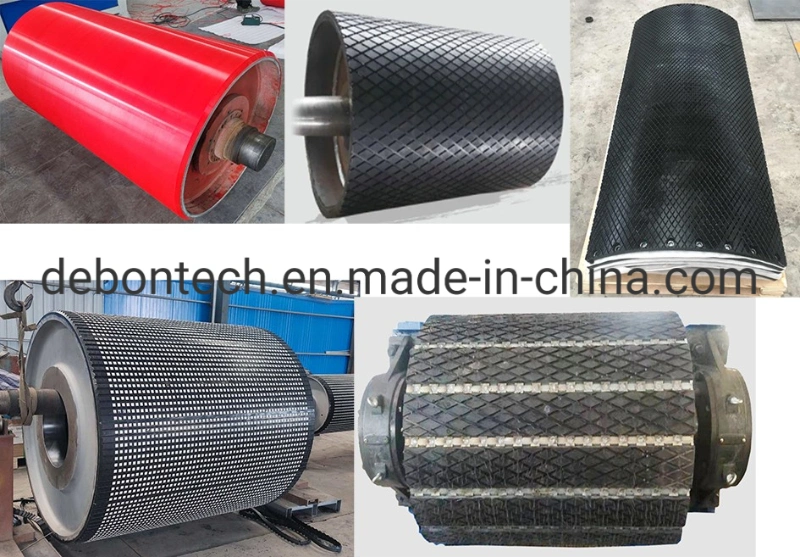

Mining conveyor head pulley with ceramic lagging.

We also provide ceramic lagging service on site or at pulley factory.

Technical Data of Ceramic Lagging:

Ceramic Tile:

1. Al2O3: 95%

2. Ceramic Hardness(Mohs): > 9t

3. Working temperature: -40 - 85ºC

Rubber:

1. Material: NR & SBR

2. Hardness: 65 ± 5 Shore A

3. Density: 1.15 ± 0.05 g/cm3

4. Tensile strength: 18 MPa

5. Elongation at Break: 550%

6. Wear loss: <=100mm3

We also produce pulley lagging rubber sheets.

About Us:

Jiaozuo Debon Technology CO, LTD is specialized in designing and manufacturing rubber and polyurethane products. Main products include: various kinds of rubber sheets, rubber lagging, rubber pulley lagging, skirt board, rubber ceramic wear liner,conveyor belt cleaner, impact bar, etc. Debon is a manufacturer with 106 employee, including 35 engineers, and with 23 years experience of producing and developing.Company is certified to ISO 9001: 2008 Qaulity management system, and rubber lagging products were certified to"SAFETY CERTIFICATE OF APPROVAL FOR MINING PRODUCTS.Our products have been exported to Australia, USA, UK, France, Chile,Russia, etc.

Main products:

1. Rubber ceramic lagging

2. Diamond rubber lagging

3. Plain rubber lagging

4. Replaceable rubber lagging

5. Conveyor belt cleaners

6. Conveyor skirt board

7. Impact bar and impact bed.

8. Wear liners

More information ,welcome to contact Mona Cheung.