Factory Ceramic Wear Cylinder-Half Alumina Ceramic Block Alumina Ceramic Lining Brick

Basic Info

| Model NO. | BMG |

| Size | Customzied |

| Bulk Order Time | 15-30 Days |

| Wear Rate ‰ | <0.1 |

| Shape | Half-Cylinder |

| Sample Time | 3-15 Days |

| Another Name | Alumina Ceramic Wear Tile |

| Transport Package | by Cartons and Pallet |

| Specification | Thickness 3-10mm |

| Trademark | TITAN INDUSTRIAL CERAMIC |

| Origin | Shandong, China |

| HS Code | 690912 |

| Production Capacity | 17000 Tons Per Year |

Packaging & Delivery

Package size per unit product 110.00cm * 110.00cm * 50.00cm Gross weight per unit product 500.000kgProduct Description

Product Details

Cylinder-Half Alumina Ceramic Block is a high performance abrasion and impact resistant liner for high impact, high pressure applications where ceramic tile may not have sufficient structural resistance and high performance rubber may not provide the required wear life. In extreme applications, the bushing can be mounted on a substrate or wear-resistant steel plate, providing structural support to the ceramic/rubber substrate and providing superior wear life where competing products cannot.

Product Advantages

High hardness: the Rockwell hardness of mosaic alumina ceramic linings pieces is above HRA90, the hardness is second only to diamond, far exceeding the wear-resistant performance of wear-resistant steel and stainless steel.Excellent wear resistance: its wear resistance is 30 times that of manganese steel and 20 times that of high-chromium cast iron. According to the customer follow-up survey for more than 20 years, under the same working conditions, the service life of the equipment can be extended by at least ten times.Light weight: its density is about 3.6g/cm³, which is only half of that of steel, which can greatly reduce the load of equipment.Strong bonding and good heat resistance: The wear-resistant ceramic sheet can be fixed on the inner wall of the equipment by various methods such as gluing, welding, and rubber vulcanization according to different equipment and working conditions.Corrosion resistance: good corrosion resistance to sulfuric acid, hydrochloric acid,strong alkali, salt, etc.

Application

For grinding conditions, cylindrical contact area is large, greatly improve grinding efficiency, reduce grinding time and save energy consumption. Used for making wear-resistant ceramic composite plate, effectively decompose the impact of materials on the lining plate.

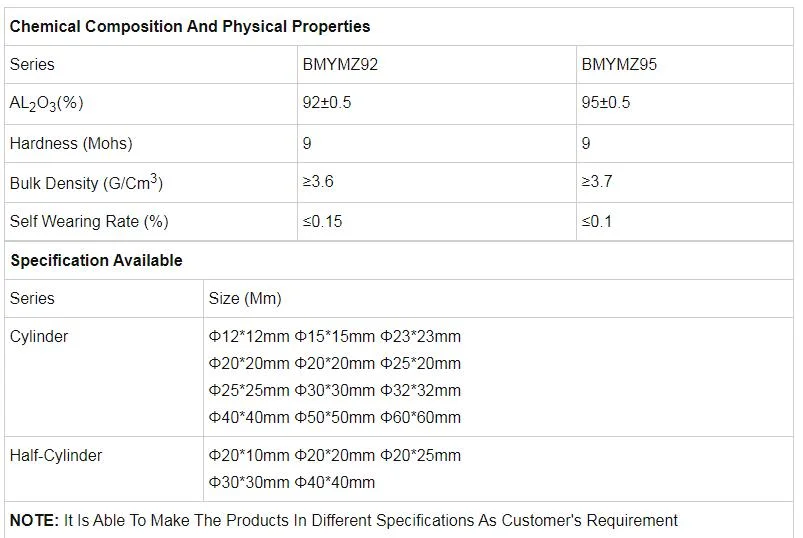

Technical Data