12mm or 15mm Head Pulley Rubber Ceramic Lagging Sheet

Basic Info

| Model NO. | OEM |

| Color | Black Rubber Sheet |

| Thickness | OEM |

| Certification | ISO |

| Condition | New |

| Warranty of Core Components | 12 Months |

| Dimension(L*W*H) | Variable |

| Logo | Available |

| Hardness | Shorea |

| Surface | Diamond,Ceramic |

| Structure | Black Rubber with Green Cn Layer |

| Appearance | PE Film Layer for Protect Both Covers |

| Application | Conveyor Pulley/Roller/Drum Lagging |

| Rubber Hardness | Shorea60 |

| Transport Package | PE Bag+Pallet/Wooden Case |

| Specification | 2m width max |

| Trademark | TRX |

| Origin | China |

| HS Code | 8433909000 |

| Production Capacity | 5000meters/Month |

Product Description

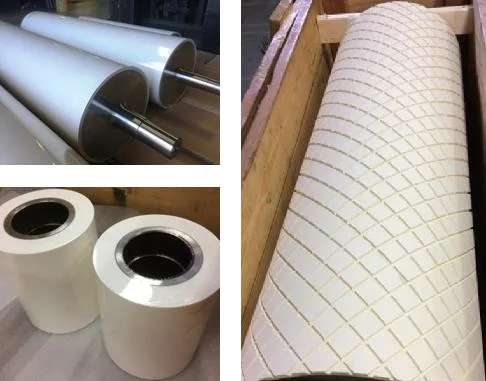

12mm or 15mm Head Pulley Rubber Ceramic Lagging sheet

Product Description

Rubber drum lagging is one type of special rubber sheet which coated on conveyor pulley , roller , drum etc., so as to protect conveyor belt from slipping . It is widely used in conveyor system of coal ming, steel mill, power plant, cement mill etc.

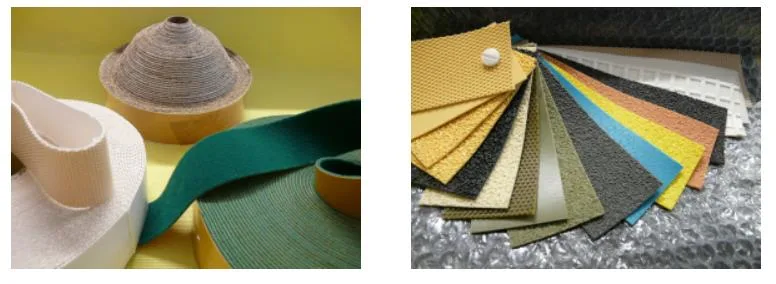

The Pulley Lagging Rubber Sheet offered by TRX come with CN Bonding Layers for better adhesion levels as also with buffed surface. The profiled patterns on the top surface, in diamond or square embossing improve belt grip and tracking on conveyors, while reducing belt wear. The Pulley Lagging Rubber Sheet is available in various grades of rubber, including FRAS and oil resistant grades.

FEATURES

- Different colors, durometers and thickness

- High release and non stick covers

- Impact and abrasion resistant

- Anti static | oil resistant | high grip surfaces

- Low friction surfaces | self lubricating

- FDA approved materials

- Heat resistant, ozone, UV, and chemical resistant

- Dual durometers / multi compositions

APPLICATIONS

- Tight specs - precision ground

- Different textured surfaces

- Profiling / indexing / crowning / grooving

- Sleeves / tube and solid bar stocks

- Thermal cast - no splice or delaminating

- Non marking covers

| Order No. | Pattern Type | Size ( T * W * L ) |

| 1 | Diamond / Plain/herringbone | 8 * 2000 * 10000 |

| 2 | Diamond / Plain/herringbone | 10 * 2000 * 10000 |

| 3 | Diamond / Plain/herringbone | 12 * 2000 * 10000 |

| 4 | Diamond / Plain/herringbone | 15 * 2000 * 10000 |

| 5 | Diamond / Plain/herringbone | 18 * 2000 * 10000 |

| Specific Gravity | 1.25 g/cm3 |

| Hardness | 60 +/- 5 Shore A |

| Tensile Strength | 150 kg / cm2 |

| Elongation | 350% |

| Abrasion | 120 mm3 |

Packaging Details

1. Standard Package for ocean shipping & air shipping2. Water-proof package3. Package Material: Plywood Case / Wooden box / Pallet4. Special packing requirements should be known in advance.

Port: Shanghai Qingdao Tianjin

Hebei TRX Rubber Products is a leading professional manufacturer of conveyor belts & conveyor accessories in China. The main workshops cover 20,000 square meters in the total 60,000 square meters of the plant. The applied technology and equipment in the advanced production lines are state of the art in the industry. The sales headquarters is located in the capital of China, Beijing with branches in domestic and abroad.

It specializes in following three series: 1) Heavy-duty Conveyor Belt, including universal EP/NN and CC Belt, Chevron Belt, Oil Resistant Belt, Abrasion Resistant Belt, Heat Resistant Belt, Fire Resistant Belt, Chemical Resistant Belt, Sidewall Belt, Flat Transmission Belts, 2) Rubber Sheets, including SBR, NBR, NR, CR, EDPM, Rubber With Insertion 3) Conveyor accessories. These three series of products conform to RMA, DIN, ASTM and ISO specifications.

Its products, honored with "The most Advanced level of Products" by the Committee of Science and Technology, have been widely used in mining and quarrying, power stations, steel plants, bulk cargo terminals, cement industry, and other material handling fields. With great success in domestic market, it has been focusing on global market with several hundreds of foreign valued customers in Asia, South America, North America, Africa and Europe.

The company mission:

2. Engage in complete solutions with conveyor belting and power transmission belting.

3. Persist in technology improvement and quality control in the whole process of production and service.

Application

These are suitable for:

| Concrete plants | Recycling and mineral processing plants |

| Waste sorting & Compost machines | Metal processing industry |

| Scrap recycling | Timber industry |

| Sawmills | Excreta & sewage sludge conveying |

| Corn, rape and soilages conveying | Solvent extraction plants |

| Paper industry |